-

Giỏ hàng của bạn trống!

0 sản phẩm

0đ

| Chính hãng (Hàn Quốc) | Trung Quốc | |

| Tên gọi | ||

| Tên gọi khác | ||

| Nhãn hiệu | Vogele | |

| Xuất xứ | Đức | Trung Quốc hoặc nước khác |

| Phân phối | VITRAC | Các đơn vị gia công, phân phối, cửa hàng cấp vật tư xe bơm khác trên thị trường |

| Mô tả | Genuine WIRTGEN milling drums, commonly equipped with an ornamental flange, ensure exceptional performance and optimum results. This ornamental milling drum flange is a special mark of quality of WIRTGEN milling drums, signifying that this is a genuine WIRTGEN milling drum. THE LEADER IN ENGINEERING DESIGN AND PRODUCTION OF MILLING DRUMS Milling drums designed and produced in the Windhagen plant are the central element of the WIRTGEN road milling machines known throughout the world. Both, then and now, WIRTGEN invests in expanding its core competence of cutting technology for the benefit of its customers. THE KEY TO VERSATILE MILLING MACHINES Operators want to use their milling machines for as many different jobs as possible. That is why WIRTGEN supplies a large variety of optional drums as part of its standard range. This allows the customer to engage in a wealth of applications for machining pavements, performing recycling contracts or in the selective extraction of hard rock. The decision to buy a WIRTGEN machine is underlined by this versatility. SPECIAL PROJECTS BRING PROXIMITY TO THE CUSTOMER New requirements are repeatedly imposed upon the construction industry and that is why almost never a day passes without WIRTGEN receiving at least one enquiry for a solution using milling technology. And solutions have evidently been found, as proved by the numerous special milling drums supplied for machines built by WIRTGEN and other companies 1 > Improving the skid resistance of the pavement 2 > Restoring the evenness/levelling 3 > Pavement markings are removed quickly and accurately with a special unit 4 > Milling off resin surfaces/ synthetic surfaces in factory halls THE MILLING DRUM GENERALLY HAS TO FULFIL THREE MAIN TASKS: > Cutting and breaking out material particles from the composite. > Transporting: Transport of loosened material particles to the area of the ejector. > Ejection of the broken material particles onto the loading conveyor. WIRTGEN offers the ideal milling drum for every application to ensure that the machine’s potential can be optimally exploited. Examples of various milling drums for small milling machines 1 > Milling drum LA15 2 > Micro-fine milling drum LA6 3 > Micro-fine milling drum LA3 4 > Water channel milling drum LA4 FB500 5 > Cutting wheel FINE MILLING IS SETTING NEW STANDARDS IN MILLING RESULTS WORLD-WIDE By special and precise finishing processes WIRTGEN can nowadays design line spacings up to 3 mm. So milling contractors are offered a multitude of new applications: Their WIRTGEN milling machines can work on sites with high-quality demands on the surface. The optionally available MCS (Multiple Cutter System) and the predecessor, FCS (Flexible Cutter System), make milling drum changes considerably easier. Examples of various milling drums for large milling machines 1 > Eco Cutter 2 > Standard milling drum 3 > Fine milling drum 4 > Micro-fine milling drum Eco Cutter rough milling drums: For greater demands on volume milling performance, Concrete milling, Complete removal of road surfaces Standard milling drums: Universal milling drum for versatile use, Removing surface and binder courses, Complete removal of road surfaces, Concrete milling Fine milling drums: For high demands on macro- and micro-profile, Removal of surface layers, incl. construction of a more even surface, Corrective milling work on roadway profiles Micro-fine milling drums: For the highest demands on macro- and micro-profile, Increase in surface grip by roughening roadway surfaces, using the micro-fine milling process, Increasing the evenness of concrete roadways, Preparation milling for surface treatment, cold paving of thin layers and other thin-layer paving, Removal of coatings from road surfaces or hall floors, Removal of markings on the road surface, Milling into markings on the road surface | |

| Tình trạng (mới/ ĐQSD) | Mới 100% | |

| Các phụ tùng/ phụ kiện đi kèm | ||

| Công dụng | ||

| Độ bền và Tuổi thọ trung bình | ||

| Những yếu tố ảnh hưởng đến tuổi thọ trung bình | ||

| Cam kết chất lượng | ||

| Bảo hành | ||

| Các loại máy phù hợp | ||

| So sánh giá | ||

| Lợi ích | ||

| Quy cách đóng gói | ||

| Phương thức Giao hàng, vận chuyển | Giao hàng tại kho, vận chuyển toàn quốc khi nhận đủ tiền thanh toán. | Giao hàng tại kho, vận chuyển toàn quốc khi nhận đủ tiền thanh toán. |

| Khả năng cung cấp | Sản phẩm có sẵn với số lượng lớn | |

| Khuyến nghị | ||

| Ghi chú/ các đặc điểm phân biệt hàng hoá chính hãng và hàng thay thế | ||

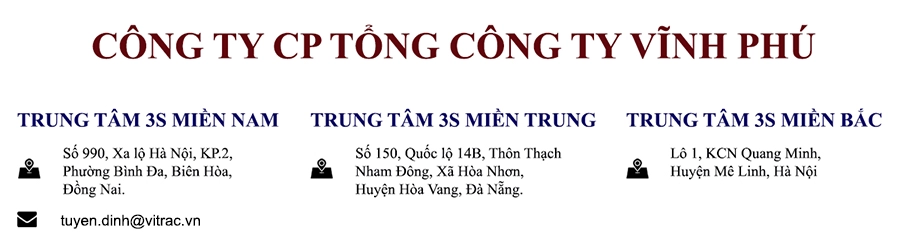

Hiện quý khách có thể tìm mua phụ tùng Wirtgen thuận tiện và dễ dàng tại các kho trung tâm của Vitrac (Phí vận chuyển sẽ được tính nếu phát sinh):

Hãy liên hệ với chúng tôi khi bạn cần tư vấn, tìm mua phụ tùng bơm, kiểm tra tình trạng máy, bảo hành bảo dưỡng thông qua Hotline 0906 702 060

Công ty Cổ phần Tổng Công Ty Vĩnh Phú tự hào là đơn vị phân phối trực tiếp các loại phụ tùng máy xây dựng chính hãng từ những thương hiệu nổi tiếng trên thế giới như: xe lu Hamm, máy xúc lật Hitachi, máy đào Hitachi, bơm bê tông Hyundai Everdigm, máy trải nhựa Vogele, xe cẩu, máy trải bê tông xi măng Wirtgen,...